Why Are Industrial Aluminum Profiles Being Used More Widely?

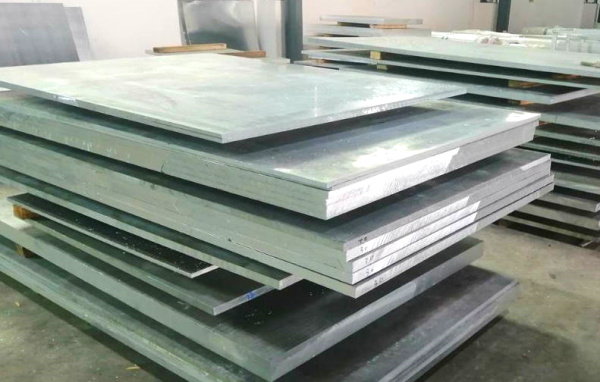

Industrial aluminum profiles are alloy materials primarily composed of aluminum. Through processes like heating, melting, and extrusion, aluminum billets are shaped into profiles with various cross-sections. By adjusting the alloy composition, manufacturers can produce aluminum profiles with different mechanical properties tailored for specific applications.

Key Characteristics

After surface oxidation treatment, industrial aluminum profiles exhibit an attractive appearance and stain resistance—oil stains can be easily wiped clean. Products assembled with these profiles use matching connectors (eliminating the need for welding), making them eco-friendly, lightweight, and easy to install, disassemble, and transport.

Advantages

Beyond modular assembly, industrial aluminum profiles offer:

-

Superior Corrosion Resistance

-

Aluminum naturally forms a dense oxide layer when exposed to air, preventing rust.

-

Additional anti-oxidation treatments (e.g., anodizing) further enhance durability.

-

-

High Strength-to-Weight Ratio

-

Pure aluminum has a tensile strength of ~80 MN/m² (1/5 of mild steel), but alloying and heat treatment can match steel’s strength.

-

-

95%+ Recyclability

-

Low melting point simplifies reprocessing, with minimal material loss (~5%).

-

-

Excellent Machinability

-

Ideal for cutting, milling, and drilling into complex shapes.

-

Applications

Aluminum profiles are expanding across industries due to their practicality, thermal/acoustic insulation, and sustainability—aligning with global green initiatives. Future advancements will drive broader adoption in:

1. Industrial Manufacturing

-

Assembly lines, conveyor systems, cleanroom structures.

-

Example: Aluminum guardrails and shelving protect heavy equipment.

2. Transportation

-

Automotive frames, doors, engine components; high-speed train bodies.

-

Benefits: Lightweight (reduces fuel consumption), corrosion-resistant, and electrically conductive for easy device integration.

3. Electronics

-

Heat sinks, enclosures, cable management.

-

Specialty profiles dissipate heat efficiently while maintaining structural integrity.

4. Medical Equipment

-

Hospital beds, stretchers, surgical devices.

-

Hygienic and rust-proof for sterile environments.

Guangdong Jingyu Aluminum Co., Ltd.

With 30 years of expertise, we customize industrial profiles (e.g., radiators, automotive battery trays, T-slot rails) for automotive, logistics, and beyond.

(Technical Note: "Tensile strength" clarifies 抗拉强度; "anodizing" specifies 防氧化处理.)

Latest News

-

062025.06

Sudden Boost for Alumina: How Long Can the Strong Momentum Last?

-

062025.06

Jiangsu Kaile Secures Patent: Metal Sheet Positioning Fixture Ensures Machining Precision!

-

062025.06

Jiangsu Kaile Metal Tech's New Patent: Flipping Device Boosts Efficiency in Ultra-Flat Aluminum Plate Processing

-

062025.06

Jiangsu Kaile Metal Develops Revolutionary Bending Machine - Patent Significantly Boosts Metal Processing Efficiency!

-

222025.05

Global Primary Aluminum Market Records 277,200-ton Surplus in March 2025

-

222025.05

6 Key Factors to Consider When Choosing Aluminum Profiles

-

222025.05

Why Are Industrial Aluminum Profiles Being Used More Widely?

-

222025.05

The Automotive Aluminum Market is Steadily Growing

-

292025.03

Jiangsu Kaile's AI-Powered Aluminum Plate Handling System Patent Approved: A New Breakthrough in Smart Manufacturing

-

152025.03

Jiangsu Kaile Secures Patent for Metal Plate Leveling Machine, Enhancing Conveyance Stability